Underground Pre-insulated Composite Plastic PPR and PVC Plastic Insulated Pipes for Cold and Hot Water

DZD 812.49

Description

Here is a clean, professional technical description of the PE-RT II Prefabricated Direct Buried Insulation Pipe system.

System Overview

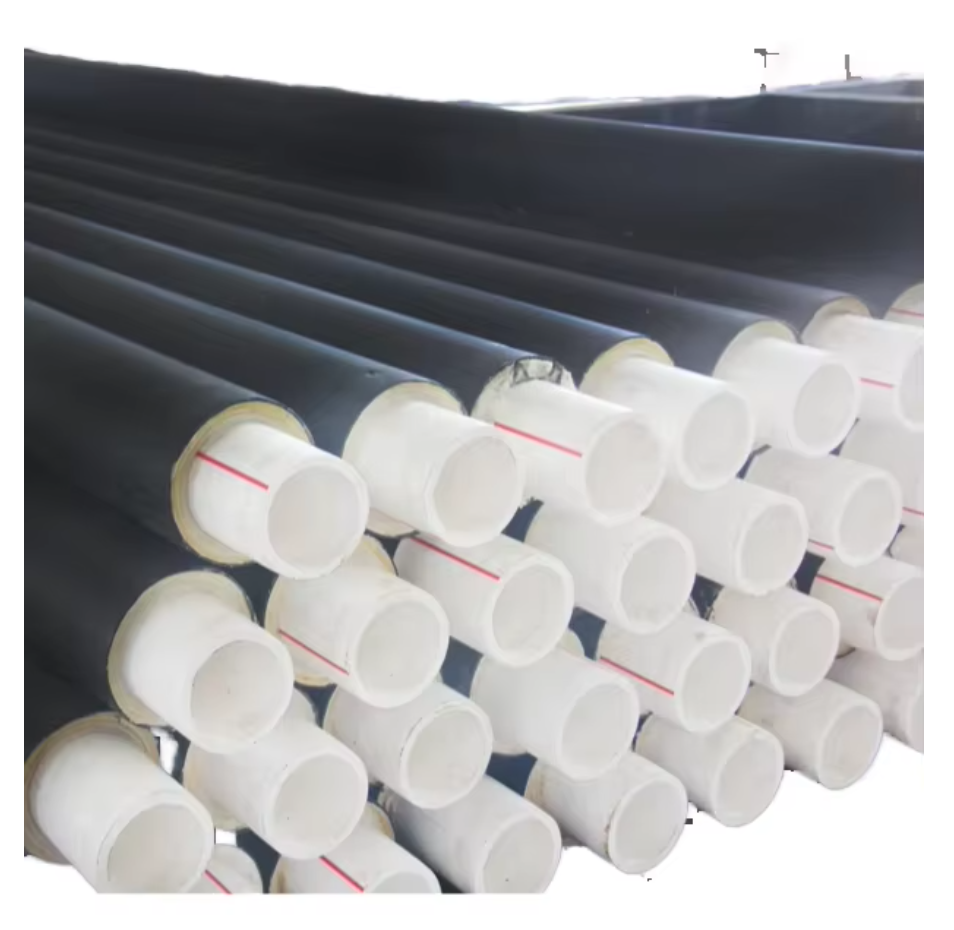

The PE-RT II insulation pipe is a high-performance, three-layer composite solution designed for modern fluid transport. It utilizes a "trinity" structure where the inner carrier pipe, the polyurethane insulation, and the high-density polyethylene (HDPE) outer jacket are bonded together to form a single, solid mechanical unit. This ensures the layers do not slide against one another during thermal expansion and contraction.

Structural Components

Carrier Pipe: Constructed from Type II Heat-Resistant Polyethylene (PE-RT II). This material provides the necessary hydrostatic strength for high-temperature applications without the need for cross-linking.

Insulation Layer: High-pressure injected rigid Polyurethane (PUR) foam. It features a fine closed-cell structure to minimize thermal conductivity and provide structural support.

Outer Jacket: High-Density Polyethylene (HDPE). This layer acts as the primary defense against mechanical impact, chemical corrosion from soil, and moisture ingress.

Technical Specifications

Diameter Range: DN25 to DN600mm.

Operating Temperature: Suitable for continuous use at temperatures below 90°C.

Operating Pressure: Rated for pressures up to 1.6MPa.

Laying Method: Optimized for direct burial in soil, but also compatible with pipe trenches and utility galleries.

Performance Advantages

Material Integrity and Durability

The use of PE-RT II material grants the system exceptional long-term hydrostatic strength under high-temperature conditions. Unlike traditional metal piping, it is immune to electrochemical corrosion and rust. This eliminates the risk of "red water" and prevents rust slag from clogging valves, heat meters, and sensitive instrumentation.

Thermal Efficiency

The integrated insulation layer significantly reduces heat loss compared to traditional lagging methods. The water-proof nature of the HDPE jacket ensures that the insulation remains dry; wet insulation is a leading cause of energy loss and pipe failure in district heating networks.

Installation and Maintenance

The system is lightweight compared to steel alternatives, simplifying logistics and onsite handling. Because the pipe is resistant to stress cracking and low-temperature impacts, it can be installed in harsh climates (as low as -40°C) without becoming brittle. The smooth internal bore also reduces friction, allowing for lower pumping energy requirements.

Primary Applications

District Energy: Distribution of hot and cold water for residential and commercial heating/cooling networks.

Industrial Transport: Conveying fluids in chemical processing, oil transport, and power plants where corrosion resistance is mandatory.

Specialized Infrastructure: Used in surface radiation heating, snow-melting systems, and hot spring water delivery.

Associated Components

To maintain the integrity of the pipeline, the following related products are utilized:

Pre-insulated Fittings: Factory-made elbows, tees, and reducers.

Jointing Kits: Heat-shrinkable sleeves and insulation materials for field-jointing.

Monitoring Systems: Optional integrated alarming lines to detect and locate leaks or insulation compromises.

Spécifications Techniques et Commerciales

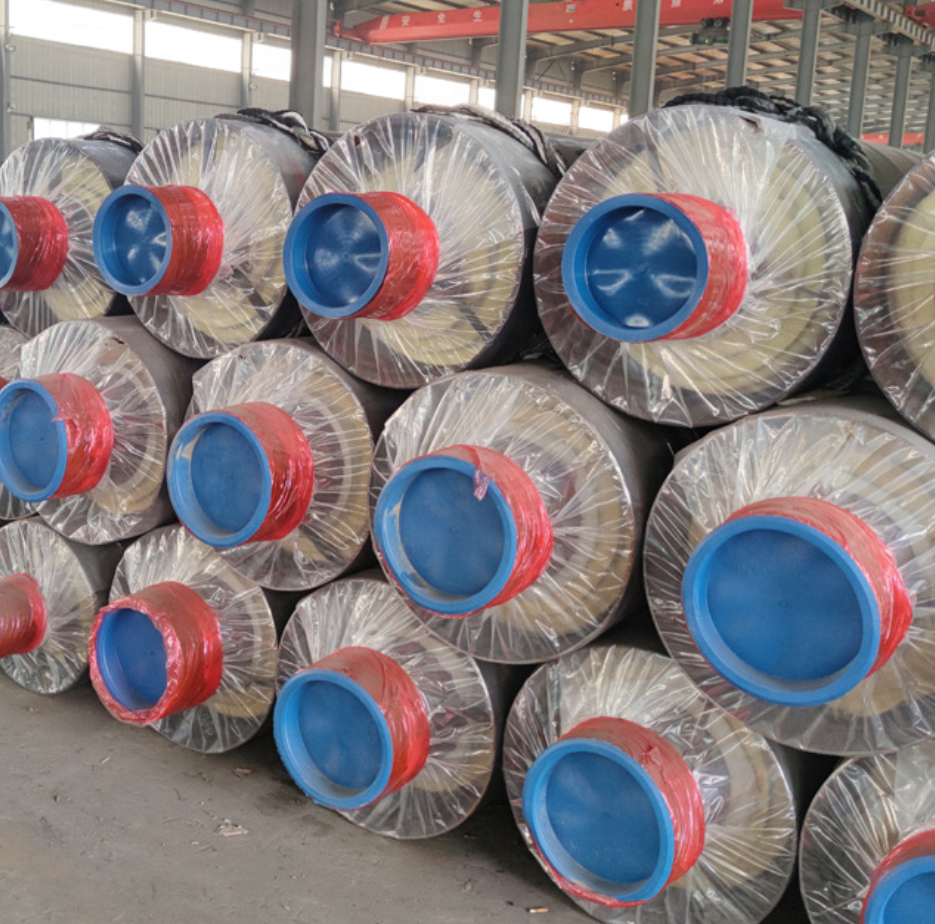

Logistique et Emballage

Shipping fee and delivery date to be negotiated. Chat with supplier now for more details.

World

Wood Box

Informations sur le Vendeur